hydros®: trenchless replacement and new installation of pipelines

KARL WEISS developed its hydros® technology for the fast and economical trenchless replacement of pressurized pipelines (connection pipelines and distribution pipelines).

Contrary to other renovation methods, hydros® technology entirely removes the brittle material of the old pipe (e.g. grey cast iron or asbestos cement) from the pipeline zone, in a complete and environmentally friendly way.

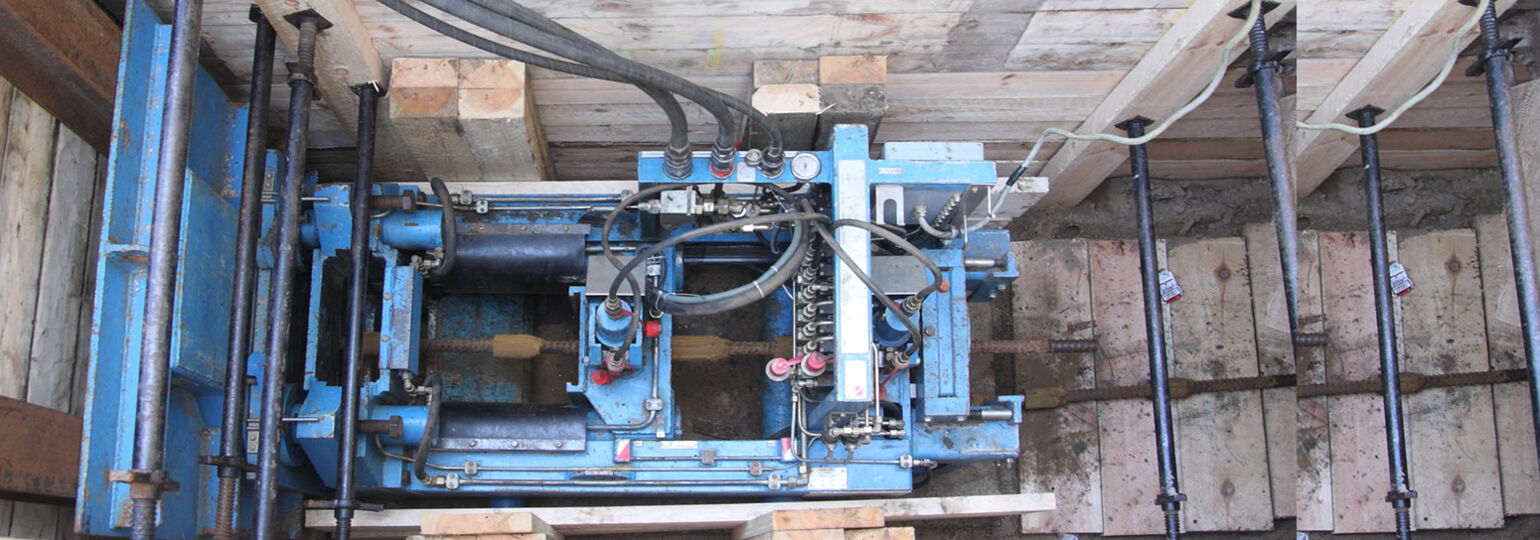

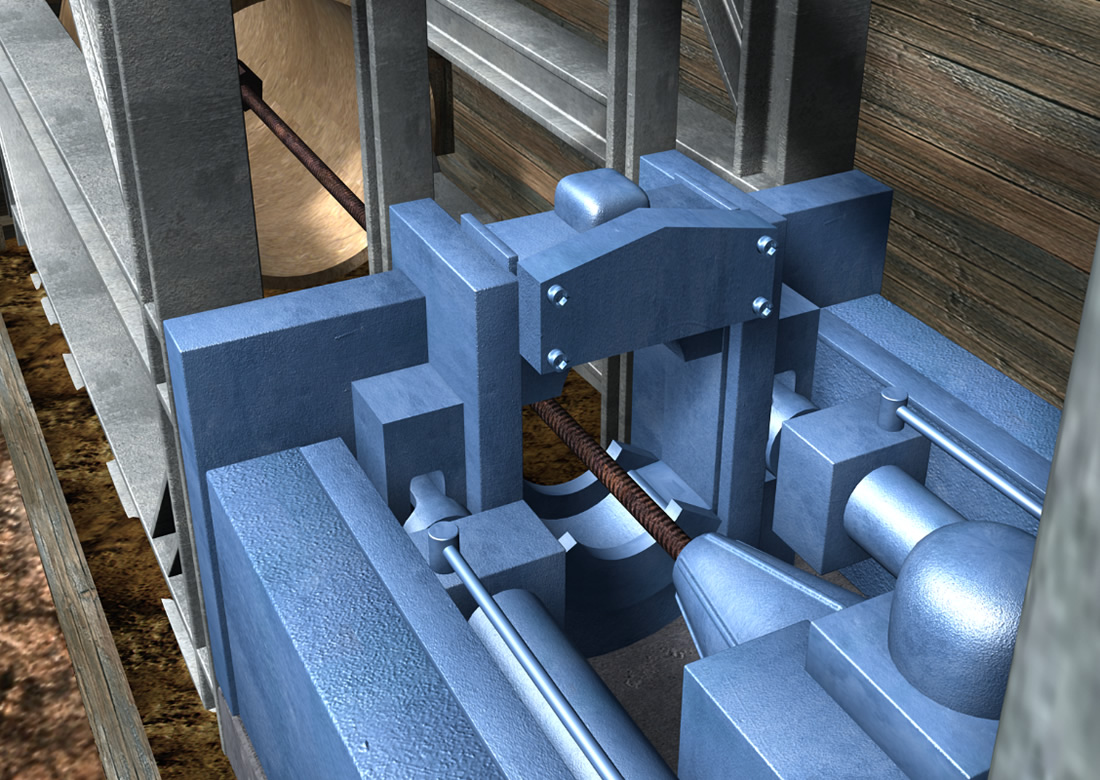

The name hydros® stands for the hydraulic pipe-pull-and-split process'. In order to replace the old pipe, a new pipe section is fixed to the end of the old pipeline with an adaptor. By using an extremely quiet (<55 dB (A)) and vibration-free hydraulic extraction device, a new pipe of any material is pulled into the earth at the same time as the old pipe is pressed out. This is why the hydros® technology is also described in the DVGW regulations GW 322-1 (A) as a press-pull-process' and according to DVGW GW 301 is certified in the special group GN 1.

Ried and tested process variations are available, from the replacement of lead house connection pipes DN 13 to asbestos cement pipelines DN 400. With additional equipment, new pipes can also be laid trenchlessly.